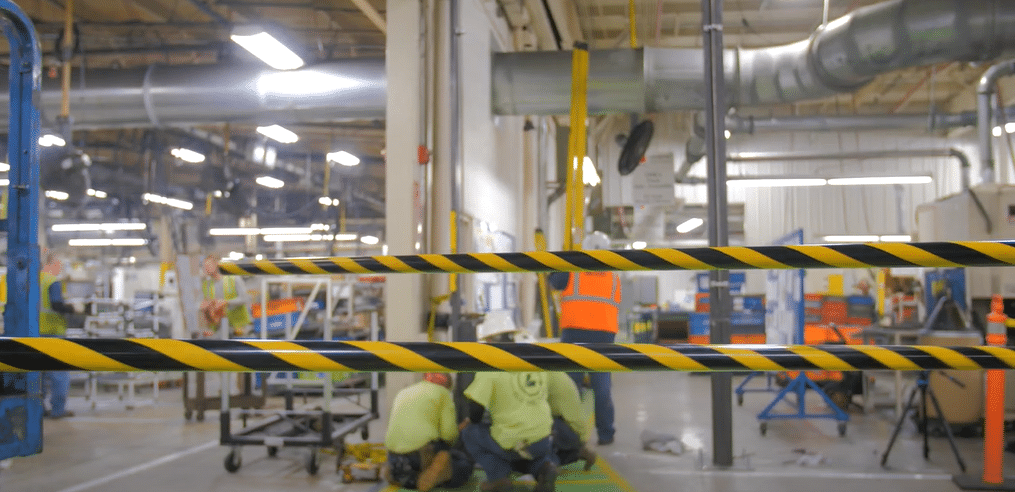

A nearby industrial plant reached out to their trusted allies at Lee Company with a cooling challenge. In need of cost-effective solutions to update chiller equipment and piping, Lee Company’s engineering team not only met their needs, but also designed an eco-friendly alternative that slashed costs by $200k. Now that’s sustainability in action!

Customer Goals:

- Replace process chiller equipment and piping in the plant staying under budget.

- Create an eco-friendly opportunity to decrease environment footprint and increase cost-savings long-term.

Solutions:

- Lee Company’s engineering team utilized the existing HVAC chiller system, decoupling it with heat exchanger separate pumps. This saved the purchasing of additional cooling equipment.

- Lee Company’s Controls group was brought in to increase the system’s efficiency.

Results:

- Big savings – Lee Company completed the project, $200k under budget!

- The design allowed for cost-reduction and long-term energy consumption cost-savings.

- Good partnerships allow for designs that meet a financial budget, but most importantly, best meet the needs of the customer.

Smart People. Dedicated Partners. Creative Solutions.

For 80+ years, customers have trusted Lee Company to handle everything from HVAC to plumbing to electrical services; we are the established experts in installation, maintenance, and repair.

Today, with more than 1,600 professionals on the team, we’re the people facility managers call when they need collaborative partners, eager to tackle the toughest challenges.

We’re ready to create a solution just right for you.

Let's Talk!